INTRODUCTION

- The duration of crop in greenhouse is the key to make the greenhouse technology profitable or the duration of production in greenhouses should be short. In this context, use of containers in greenhouse production assumes greater significance. The containers are used for the following activities in greenhouse production.

- Raising of seedlings in the nursery

- Growing plants in greenhouses for hybrid seed production of flowers

- Growing plants for cut flower production.

Growing potted ornamental plants.

- Choosing greenhouse bench materials and design can be a difficult decision, due to wide choice of products available to the grower today. In this chapter we will learn common designs, materials and considerations in choosing containers, benches for commercial application.

- BENCHES

Floor as benches

Growing plants directly on the floor in conjunction with ground floor heating systems using the floor for growing plants is gaining popularity, but the cement must be laid exactly level in order to achieve an even distribution of water when flooding floors. Porous concrete floors may be expanded in width to serve as “benches”. The main advantage is the porosity offered and the lowered cost from bypassing above ground structures. This system works well for some species. However, the added fatigue on employees may not be worth the initial savings when considering the strain of working at an awkward position.

- Raised Benches

Bench arrangements

Maximum utilization of growing facilities is largely based on the amount of growing area achieved. Benches in the peninsular design may result in a greater growing area than if they were in a longitudinal arrangement. The peninsular design also allows many species to be conveniently segregated, which can be a real advantage for retail growers. However, many growers have found routine tasks such as watering much easier on longitudinally placed benches

Lastly, non-stationery benches, which provide even more growing space, are gaining popularity with growers. Movable benches known as rolling benches, can increase efficiency up to 90 percent of the floor space. Bench platforms are moved by a crank at the end of the bench from side to side. Some can be moved by hand by sliding the benches over the top of long steel poles. Aisles are created where the grower wants to work at any given time. Rolling benches are easy to move by practically any labourer, which is an added bonus. Movable benches, however, are not appropriate in a retail setting or where plants must be accessed frequently. Retailers are better served by staying with conventional benches such as the longitudinal, peninsular, or other comparable type designs.

- Bench Space Efficiency

Benching efficiency is defined as the square feet of bench space to the entire greenhouse floor area. This number is expressed as a percentage.

Examples: A grower chooses a longitudinal bench arrangement in a greenhouse 30′ x 80′ or 2400 square feet of floor area. He decides to use 3-foot wide benches and 2.5-foot wide aisles and allows four feet at the end of the benches. The greenhouse has a benching efficiency of [5 (number of benches) x 72 (length of each bench) x 3 (width of bench)] \ (30 x 80 greenhouse dimensions) x 100 = (1080/2400) x 100 = 45%.

However, if the benches were widened to four feet and 74 feet long, allowing a three-foot turn around rather than four feet as before, efficiency could be increased to 49 percent [(4 x 74 x 4) / (30 x 80) x 100 = 49%]. To further increase efficiency, the benches could be widened and the aisle widths reduced.

If the grower looks at the same greenhouse with 2400 square feet floor space, but this time designs a peninsular bench arrangement, he will find that the peninsular design will increase the growing area even more. Still greater efficiency could be realized with rolling benches.

Bench Design

An alternative to conventional benching systems is the ebb and flow (flood or sub irrigation) benches. Metal or wood benches are replaced with watertight, molded plastic trays. Trays are periodically flooded with water and desired fertilizer concentration, which can be taken up throughout the plants via capillary action. This system has such advantages as reduced and uniform applications of water and fertilizer. Excess water and fertilizer are collected after each flood and drain cycle to be recirculated later. Up to 50 percent reductions in water and fertilizer savings have been reported. Labour costs will also be reduced since the entire bench can be watered at the same time. This may not be feasible if plants with dissimilar water requirements are grouped together on each bench. An added benefit is that foliage will stay dry and plants can be grouped closely for greater production efficiency. Ebb and flow bench manufacturers have also designed trays to be incorporated into a rolling bench system for even greater versatility. This bench system should be given serious consideration with ever increasing restrictions on water and fertilizer runoff.

Materials for Benches

Wooden Benches

Locust, cedar, redwood, and cypress are all woods highly resistant to decay. Paint benches before use with copper naphthenate or other preservatives to augment the natural decay resistance of the wood chosen. When redwood is chosen, iron and steel will corrode from naturally present decay inhibitors. Therefore, choose metals such as aluminum, zinc, or brass nails, screws, and bolts. Benches may be all wood or in combination with a different material for the base. Often, expanded metal or welded wire of one inch or smaller mesh is used. While expanded metal is more expensive, it does not sag like welded wire. Besides decay, wood may warp and often absorbs soils, chemicals, etc. which cannot be adequately removed. When wood is chosen, higher maintenance will be required on a regular basis.

Concrete

Some growers built concrete forms and pour entire benches, including the legs (supports), all at once. These benches are permanent and do not allow for change later. Concrete benches are durable and will not require additional treatment to prevent decay such as with wood. They may be reinforced with steel rods, when poured, for additional durability. Lastly, consider drilling holes in the base of the bench for proper drainage.

Metal

Entire metal or steel benches are used alone or in combination with another material. Advantages of galvanized metals over wood are the longevity and resistance to rot and decay. Metal benches may be expensive to install initially, but can be considered a one-time cost. Also consider the lowered maintenance costs when these types of benches are used.

Temporary/Portable Benches

Plastic

Although plastics are becoming more common for bench beds, plastic frames are not always desirable. They are often not as durable or able to support as much weight as other benching materials. However, in a retail setting, prefabricated benches can be purchased which are lightweight and, thus, portable. These are also available mounted on rollers, making them particularly convenient in retail settings. Also, maintenance on plastic benches is again considerably less than for wood

Pallets

Another portable bench system can be inexpensively constructed by placing pallets on cement blocks for support. Besides the low cost, this portable display can be easily and quickly disassembled.

Bench Supports

Cement blocks are commonly used to support bench tops, particularly if they are not intended to be permanent. Permanent benches may also be supported in this fashion. Additionally, steel poles are often used for bench support. Plastic bench supports are becoming more popular, but again they are often not as strong, and in many cases are most appropriate for temporary retail displays. When wooden supports are used, it is especially critical to chemically treat them for decay, at least the area which will be submerged in the soil. The same preservatives which may be used on the growing surface of the benches are appropriate. Also, by pouring concrete footings, the structural integrity of the bench supports may be reinforced.

CONTAINERS

Selection of suitable containers depends upon the crop to be produced in greenhouse, plant characteristics like crop stage, duration, vigour, growth habit, root system, etc. Generally long duration, deep rooted and vigorous crop plants require bigger containers compared to short duration, shallow and less vigorous ones. The containers provide optimum condition for germination of seed and growth and development of transplants.

- Advantages of containers in greenhouse production

Increases production capacity by reducing crop time.

High quality of the greenhouse product

Uniformity in plant growth with good vigour

Provide quick take off with little or no transplanting shock.

Easy maintenance of sanitation in greenhouse

Easy to handle, grade and shift or for transportation.

Better water drainage and aeration in pot media.

Easy to monitor chemical characteristics and plant nutrition with advanced irrigation systems like drips.

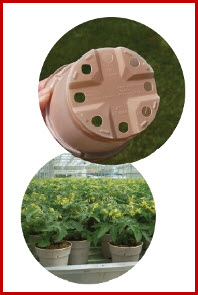

Types of containers

Plastic

- The most common and inexpensive type of planter is the plastic planter. These are available in a multitude of sizes, shapes and designer colors and range in price from downright cheap to the more expensive designer lines. These planters are available with or without drainage trays and with smooth or textured surfaces. These containers are water-tight and non-porous.

Ceramic:

Ceramic planters are usually slightly more expensive than plastic planters. They are also available with or without water drainage trays. Trays are a must for ceramic planters which do not have sealed surfaces, as they are porous and will “bleed”. Ceramic containers come in natural, textured surfaces or painted and glossy finishes. Some are hand-formed, imperfect and artistic. Some are geometric and have a high-tech look. Ceramic planters can create a quality custom look and they come in a wide range of prices.

Wood

Wood planters are less common than other types. Custom planters commonly constructed in wood, come in a variety of finishes and can give a particular decor a natural look. These planters should be lined with a non-porous material because wood can stain and rot if water-soaked. Wooden planters can be treated with a preservative, using only products recommended for applying to wooden greenhouses and avoiding those like creosote that could harm the plants.

Fiberglas

Fiberglass planters are used widely in commercial plantings. The surface is durable and easily formed into different custom shapes for any look. They can be given many different surface textures and painted any colour or pattern imaginable. They are water-tight; ridges are often built into bottom surfaces to provide drainage isolation. Fiberglass planters are available to the homeowner, but primarily through designer outlets and catalogues. They are considerably more expensive than plastic planters.

Metal

Metal planters provide a nice accent for plants. The most common metals used in planter construction are brass, copper, stainless steel and aluminum. Wrought iron is also commonly used as a decorative container. Metal surfaces range from antique to highly polished to brushed. Metals require more maintenance than other surface materials. Treating of surfaces with sealants can reduce the tendency for tarnishing and minimize maintenance. Most metal containers do not provide drainage and are used primarily as outer covers for plant containers. Prices range from moderate for simple thin brass and copper containers to expensive, heavier, intricate units. Metal planters are available in all shapes and sizes.

Clay/Terra Cotta:

Clay pots can be used for interior display. Because they are porous, it is necessary to place pots on a waterproof tray to catch excess water and prevent bleeding of moisture through the pot onto carpet, floor or other surface areas.

Alternative containers

With the ever-increasing customer demand for sustainable greenhouse products, many growers are exploring ways to make their businesses more ‘green’ both in terms of environmental impact and public perception. Even though plastic containers meet the production needs of the nursery and greenhouse industry, plastic derived from petroleum is nonrenewable. Furthermore, used plastic containers are primarily disposed in landfills given limited access to recycling centres, high collection labour costs, chances of chemical contamination, photo degradation, and liability for poorly sanitized containers. Green industry stakeholders have identified the use of biodegradable container alternatives as a way to improve the sustainability of current production systems.

Types of Alternative Containers

Alternative containers similar to traditional petrochemical based plastic have been developed for use in greenhouse production. Alternative containers are classified based on the nature of degradability at the end of production life

Types of alternative containers available in market

Name of Product

Material

Picture

Plantable

Biopot

bamboo fiber

Coir pot

coconut coir fiber

CowPotTM

composted cow manure and natural fiber

DOTPotsTM

spruce fiber, peat moss

Ellepot®

Paper

Fertil Pot

spruce wood fiber and peat moss

Jiffy-Pot®

Peat

Kord Fiber pot

wood and paper

Net PotTM

rice hull

SoilWrap®

Mirel® (biopolymer)

Straw Pot

rice straw

Western Pulp pot

molded wood pulp, recycled paper

Compostable

Carbon Lite

Starch

Ecotainer

plant starch (PSM)

Kord Fiber Grow

recycled paper or cardboard

Large Pulp Pots

wax permeated wood pulp

TerraShellTMPot

Poly Lactic Acid (biopolymer from corn starch)

Rice hull pot

rice hull

Speedypot

peat and PLA biopolymer wrapper

Wax tough pot

wood and paper coated in wax

Recycled plastic geotextile

These containers are produced from recycled plastic bottles that would have ended up in a landfill. The used bottles are turned into a liquid and blended with biodegradable natural fibers, such as cotton, jute, vegetable fibers or bamboo to create a mixture that when heat pressed bonds to produce a fabric like geotextile that is sewn into a container to grow plants. These containers are not biodegradable or compostable but will slowly disintegrate to a point that leaves behind a much reduced carbon footprint. An example of this type of product is the Root PouchTM.

Compostable

The containers are intended to be separated from the plant at planting and composted separately as they are not quickly or completely biodegradable in the landscape. Most bioplastics as well as hard rice hull and thick-walled paper/fiber containers intended for production of long term crops fall into this category. Industrially compostable containers may not break down in a typical backyard compost pile due to the low and inconsistent temperatures, moisture, pH, aeration and microbial populations. ASTM D6400 is the main standard developed by American Society for Testing and Materials (ASTM) for certification of industrially compostable plastics in the United States (ASTM, 2004).

Plantable

The containers are intended to be planted in the soil together with the plant. These containers are intended for short term pre-production and are expected to reduce transplanting shock, save transplanting time and cost, as well as to avoid used container disposal. For these products to live up to these claims, it is imperative that the containers do in fact break down quickly once planted into the soil to allow rooting into surrounding soil and not require removal when the bed is replanted. The rate of container biodegradation following planting depends on the container material, nitrogen, moisture, temperature, pH, microbes, etc. of the soil in which the containers are planted. The highest container decomposition was found with CowPotTM, which has cellulose and nitrogen from dairy manure. More moderate degradation was found for peat, rice straw and wood pulp containers, the lowest level of decomposition observed during the trial period was associated with coconut fiber containers due to their high lignin content. Slow container degradation could cause root circling resulting in restricted water and nutrient movement and ability to adequately anchor woody perennials.

Sources of Alternative Containers

Pressed Fibre

There are a wide variety of hot-pressed fiber containers available in the market. These are constructed from fibrous materials such as rice hulls, wheat, peat, wood pulp, spruce fibers, coir (coconut fiber), rice straw, bamboo or mixed with composted cow manure. Fiber containers are semi porous and promote water and air exchange between the rooting substrate and surroundings. These containers may be biodegradable or compostable. Some include a natural or synthetic binding material such as resins, glue, wax, latex and even cow manure. Pressed fiber containers tend to have varying degrees of rigidity, material strength, and decay resistance.

Bioplastics

Bioplastics perform just like traditional plastics and are created from either biopolymers or a blend of bio and petrochemical based polymers. Bio based plastics are obtained using renewable raw materials such as starch or cellulose from organic feed stocks: corn, potato, cassava, sugarcane, palm fiber, beet, proteins from soybean or keratin from waste poultry feather, and lipids from plant oils and animal fats and are usually blended with fossil fuel-based polymers to reduce cost and/or enhance performance. Petrochemical-based polymers are derived from petrochemical refining. There are 3 main types of bioplastics currently available in the market. (a) Starch-based plastics (b) Poly lactic acid (PLA) (c) poly-3-hydroxybutyrate (PHB). They can be processed easily on equipment designed for petrochemicals eliminating the need to develop new industrial machinery.